ANSYS 2020 R1 Digitally Threads Simulation Across Product Lifecycle Processes

PITTSBURGH, Jan. 28, 2020 /PRNewswire/ -- Companies are accelerating digital transformation by integrating cutting-edge ANSYS (NASDAQ: ANSS) technology across product lifecycle processes through new functionalities released today in ANSYS 2020 R1. From improving product development with ANSYS Minerva to running complex simulations with substantially streamlined workflows with ANSYS® Fluent® to optimizing electromagnetic design processes with ANSYS® HFSS™, ANSYS 2020 R1 enables companies to pioneer trailblazing innovations and create highly cost-effective designs.

As simulation impacts virtually every product development decision, users must address considerable scale and complexity challenges of interoperability, data and process management, high-performance computing (HPC) integration and traceability. Additionally, sophisticated multiphysics simulation and optimization assets must be widely available throughout engineering teams and across product lifecycles. ANSYS 2020 R1 addresses this with portfolio-wide upgrades and improvements to ANSYS Minerva — enabling customers to connect simulation and optimization to their larger product lifecycle processes.

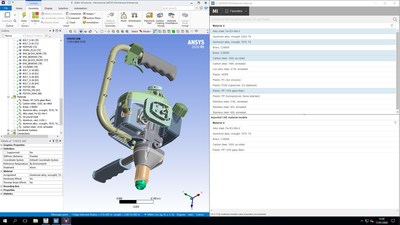

ANSYS Minerva helps companies transform simulation intellectual property into a valuable and controlled corporate asset, capture best practices and digitally thread simulation and optimization more broadly across the enterprise than ever before. Minerva now incorporates advanced technologies for significantly improving workflows and enhancing simulation process and data management (SPDM). This includes dashboards that drive improved decision support, dynamic 3D visualization tools for exploring model data, a state-of-the-art system for managing change and ensuring reliability of information.

OptiSlang — a technology now owned by ANSYS as a result of the recent acquisition of Dynardo — now teams with Minerva's SPDM solutions to help users reduce development time and expedite the evaluation of affordable optimal design alternatives.

"Navigating digital transformation is about adapting to a constantly evolving environment and using existing tools and data in new ways. With use of simulation expected to expand in the coming years, Minerva is important to Eaton and plays a key part in our larger, enterprise-wide digital prototyping and additive manufacturing (AM) initiatives," said Todd Earls, vice president of Information Technology at Eaton. "Additionally, traceability and management are essential for efficiency and there are many steps necessary to design and manufacture parts using AM or other processes. ANSYS Minerva will help make our user experience more streamlined than it is today."

An interoperable knowledge management application engineered with an open and vendor-neutral architecture, Minerva integrates with engineering teams' ecosystem of simulation tools and enterprise systems and streamlines collaboration and traceability across teams based around the world.

"Customers across virtually every industry seek to radically improve how they leverage simulation, optimize designs and share data to spur innovation and create products more efficiently," said Eric Bantegnie, vice president and general manager at ANSYS. "Minerva's improvements help fuse simulation and optimization processes across the enterprise, establishing simulation-based design optimization workflows as a dynamic standardized process for exploring and improving product performance. In addition to Minerva, ANSYS 2020 R1 delivers numerous state-of-the-art upgrades across our portfolio designed to inspire innovation, slash development costs and speed products to market."

Pioneering Major Advancements in Simulation

ANSYS 2020 R1 delivers upgraded capabilities for flagship simulation platforms including ANSYS® Mechanical™ and ANSYS Fluent that help customers strengthen their digital thread to drive innovation and overcome design complexity challenges. Additionally, this new release upgrades ANSYS HFSS and ANSYS® Maxwell® to help customers substantially enrich their electromagnetic design processes.

ANSYS 2020 R1 empowers ANSYS Mechanical users to go further than ever before with added features and enhancements to better handle complex, highly nonlinear and massively large models. Additional functionality streamlines workflows, including post-processing of reinforcements and easy drag-and-drop of external models right into ANSYS Mechanical.

Leveraging ANSYS distributed compute services (DCS) helps engineers run Mechanical and Fluent design iterations with increased speed, delivering new products to market faster than ever.

"Radiate uses simulation from the very early stages of the development process. To fully explore the entire solution space for a given problem, we use ANSYS DCS to push our development to the limit of what is possible," said Simon Grob, head of simulation engineering at Radiate Engineering & Design AG. "DCS empowers us to evaluate a variety of different solution options and optimize designs in the shortest possible time."

In ANSYS' fluids suite, Fluent introduces new features that make it easy for nearly anyone — from novices to experts — to effectively run high-quality, complex multiphase computational fluid dynamics simulations using a simplified and streamlined workflow that sets up simulations 25% faster. Fluent users are additionally supported by an immersive and highly intuitive graphical user interface, enabling them to directly interact with models and graphical elements to help speed set up.

Fluent's new release also introduces a new algebraic interface area density model that accounts for differences in drag and interfacial area to accurately simulate complex multiphase transitions between liquid and gas flows. This delivers better simulation accuracy for designing nuclear reactors, oil and gas pipelines and many other applications.

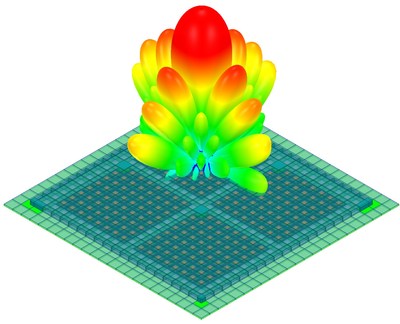

The electromagnetic suite introduces advances in ANSYS HFSS for quickly and accurately modeling antenna arrays — key for enabling 5G. For high-speed electronics, HFSS delivers remarkable solving speed for very large simulations, recently slashing compute time from 50 hours to 5 hours for a specific benchmark.

New upgrades in the area of electronics design enable users to predict and resolve printed circuit board electromagnetic interference and run transient thermal analyses to ensure highly reliable designs.

Also in the electromagnetic suite, ANSYS Maxwell delivers a new multiphysics solver designed to predict noise and vibration in electric vehicle (EV) powertrains, boosting EV overall reliability and performance.

In addition to delivering quiet rides, next-generation EVs will also be safer. Through its acquisition of Livermore Software Technology Corporation (LSTC), ANSYS will enable OEMs to accurately predict a vehicle's reaction and passenger safety in the wake of a collision. Leveraging LSTC's leading-edge simulation will greatly reduce — and possibly eliminate — the requirement for expensive physical prototype testing.

AM customers can now use ANSYS Additive Prep to write build files for multiple AM machine types, including EOS and SLM. This significantly streamlines the development of AM manufactured parts by eliminating the use of third-party software.

ANSYS' materials suite updates ANSYS® GRANTA MI™, focusing on optimizing user experience for enterprise-wide implementations. The suite also introduces ANSYS GRANTA MI Pro, a new fast-start data management solution for design and simulation — broadening access to the numerous benefits of material intelligence.

Users will explore designs faster than ever with ANSYS® Discovery™ Live's new steady-state fluids solver and an updated structural solver which also improves accuracy for thinner geometries. Users will also receive upfront design insights with the addition of manufacturing constraints and multi-analysis optimization for generative design.

Getting More from ANSYS Cloud

In ANSYS 2020 R1, ANSYS® Cloud™ introduces new licensing options to enable greater business flexibility. Companies can cost optimize cloud software usage by mixing elastic (usage-based) and traditional (leased or paid-up) licensing while accessing on-demand compute resources.

"ANSYS Cloud has been a game changer from a productivity standpoint. We can simultaneously submit multiple ANSYS Mechanical jobs covering different load cases without encountering scheduling or memory capacity concerns," said Tim Marvel, P.E., vice president, Business Development & Technology at Downing Wellhead Equipment. "For each design, we evaluate 5-10 options with multiple load cases. ANSYS Cloud has reduced the time of each job from 20-25 hours to only 2-4 hours."

Improving Automotive Safety, Design and Acoustics with ANSYS VRXPERIENCE

From leading-edge optical simulations to new applications for embedded design, ANSYS 2020 R1 delivers new digital thread enhancements across the board to boost the safety, reliability and aesthetics of next-generation autonomous vehicles (AV).

ANSYS® VRXPERIENCE™ provides cutting-edge innovations for sensor, human-machine interface (HMI) and sound simulations. ANSYS VRXPERIENCE Sensor provides a reduced order model (ROM) radar simulation for industrial automation applications, enabling engineers to quickly test and improve the accuracy and robustness of AV radars in edge cases. ANSYS VRXPERIENCE HMI offers a streamlined process to test HMI prototypes faster than ever. ANSYS VRXPERIENCE Sound offers an increased user experience through an improved workflow and user interface that assists uses in quickly detecting and analyzing engine noise, helping engineers pivot their design to create a quieter cabin.

"Acoustic comfort in helicopter cabins is critically important for pilots and passengers. Airbus Helicopters uses ANSYS VRXPERIENCE Sound to accurately listen to and analyze sound, troubleshoot unusual noise issues identified in flight and perform fast psychoacoustic indicator calculations to estimate acoustic comfort," said Julien Caillet, head of department, acoustics at Airbus Helicopters. "By using VRXPERIENCE Sound, we definitely see an unparalleled time gain. ANSYS helps our team make earlier design choices, reduce physical testing and shorten problem-solving time."

ANSYS 2020 R1 introduces ANSYS VRXPERIENCE Light Simulation to simplify automotive product design illumination, delivering engineering-grade light simulation to studio designers. VRXPERIENCE Light Simulation combines visual design and advanced engineering review by connecting Autodesk VRED design visualization software and ANSYS' physics-based lighting simulations. This delivers a photorealistic visualization of vehicle interior and exterior lighting, enabling users to spend substantially less time and money on physical prototype development.

Boosting Cybersecurity with ANSYS medini analyze

The latest release of ANSYS® medini analyze addresses the increasing market need for systematic analysis and assessment of security threats to AV cyber-physical systems — beginning early in the system design. This helps automakers model the limitations and weaknesses of AV system components and environmental conditions to provide state-of-the-art cybersecurity.

Illuminating Simulations with ANSYS SPEOS

ANSYS® SPEOS ™ incorporates a leading-edge model for camera simulation to increase the accuracy of advanced driver assistance systems (ADAS) and AV simulations, creating results that are closer to reality. SPEOS also stretches the limits of lighting simulation, empowering users to quickly and efficiently model numerous types of lighting variations that AVs will experience on the road and optimize AV lighting system performance.

"Mazda is always eager to introduce smarter technology into their vehicles, from ADAS systems to smart headlamps, tackling the challenges to achieve high-quality requirements and scheduled targets," said Tohru Yoshioka, deputy general manager at Mazda. "Providing physics-based design and testing of optical features, ANSYS SPEOS and VRXPERIENCE are extensively used at Mazda to perform early and iterative digital design and optimization of systems, from adaptive driving beams using complex matrices of LED units to camera systems used in AV-ADAS technology. This enables us to significantly reduce the physical prototyping and testing phase of these systems while improving safety and fast-tracking time to market."

Improving AV Safety-Critical Software Development with ANSYS SCADE

The latest version of ANSYS® SCADE further accelerates AV embedded control software design, incorporating several new capabilities designed to reduce the development time and cost for automatic code generation of safety-critical software throughout the development cycle by over 50%.

ANSYS 2020 R1 extends the scalability of ANSYS SCADE Vision to further accelerate testing activities and improve safety of large, AI-based perception software projects by creating direct connections to data lakes on customer cloud clusters.

Slashing Development Time and Boosting Productivity with ANSYS Twin Builder

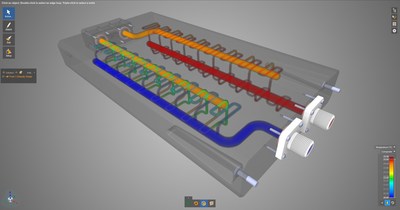

ANSYS® Twin Builder™ now includes ANSYS Twin Builder Battery Wizard which will shorten development time of building, simulating and testing an entire battery-powered electrical system across industries.

"A123 uses ANSYS Twin Builder to perform thermal simulation of their 48V battery pack development. With the help of the simulations, A123 can determine thermal dependency on electric performance, design cooling supply, calculate temperature distributions and predict battery life," said Shawn Zhang, senior manager, Simulation Engineering at A123 Systems. "A123 also utilizes ANSYS Twin Builder's ROM technologies for simplifying complex 3D thermal simulation which significantly reduces the simulation time from days to few seconds while keeping the required simulation accuracy."

Additionally, ANSYS Twin Builder features innovative improvements to its industry-leading ROM capabilities including the capacity to capture higher non-linearity components and the integration of a tool-agnostic static ROM builder to enable field visualization for ROMs. Twin Builder also provides improved workflows for Modelica and runtime generation.

Power and Thermal Reliability Solutions for Automotive and 5G Semiconductor Electronics

New updates to ANSYS® Redhawk-SC™ help engineers gain better insights into more complex designs and substantially slash simulation runtime — delivering significant performance and accuracy improvements.

Also in 2020 R1, the ANSYS® Totem™ and ANSYS® RedHawk™ product family are certified to support a comprehensive list of advanced FinFET nodes and 2.5D/3D-IC packaging technologies. This empowers customers to address the growing multiphysics challenges of power, thermal and reliability in ultra-large and high-performance SoCs that are at the heart of AI, 5G and automotive applications.

About ANSYS, Inc.

If you've ever seen a rocket launch, flown on an airplane, driven a car, used a computer, touched a mobile device, crossed a bridge or put on wearable technology, chances are you've used a product where ANSYS software played a critical role in its creation. ANSYS is the global leader in engineering simulation. Through our strategy of Pervasive Engineering Simulation, we help the world's most innovative companies deliver radically better products to their customers. By offering the best and broadest portfolio of engineering simulation software, we help them solve the most complex design challenges and create products limited only by imagination. Founded in 1970, ANSYS is headquartered south of Pittsburgh, Pennsylvania, U.S.A., Visit www.ansys.com for more information.

ANSYS and any and all ANSYS, Inc. brand, product, service and feature names, logos and slogans are registered trademarks or trademarks of ANSYS, Inc. or its subsidiaries in the United States or other countries

ANSS-G

|

Contact |

Media |

Mary Kate Joyce 724.820.4368 |

|

Investors |

Annette N. Arribas, IRC 724.820.3700 |

|

![]() View original content to download multimedia:http://www.prnewswire.com/news-releases/ansys-2020-r1-digitally-threads-simulation-across-product-lifecycle-processes-300994043.html

View original content to download multimedia:http://www.prnewswire.com/news-releases/ansys-2020-r1-digitally-threads-simulation-across-product-lifecycle-processes-300994043.html

SOURCE ANSYS, Inc.