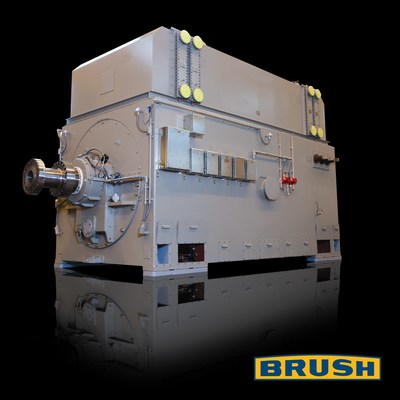

Brush Group Optimizes Turbogenerator Design With ANSYS Multiphysics Solutions

The Brush Group chose ANSYS simulation to reduce the six-month lead time for new design generator manufacturing and to reduce the extensive costs and complexity of design modifications.

"The smallest units weigh at least 40 tons, take up to six months to manufacture and contain many small design change opportunities, some with unmeasurable aspects. So it is simply impossible to take each new design option to the point of physical prototyping," said Sarah Allen, generator development manager, Brush Turbogenerators. "Simulation software, especially integrated, multiphysics simulation, is vital to reduce the variables that these design changes create in a virtual environment before moving to production."

The Brush Group is leveraging ANSYS solutions for structures, fluids and electronics. The tools accurately simulate the impact of mechanical changes on the airflow within a turbogenerator. ANSYS computational fluid dynamics solutions simulate this airflow, which is crucial as increased performance of the turbogenerator depends on having a uniform operating temperature and must remain within national and international standard limits. Finally, ANSYS electronics solutions simulate the electromagnetic impact of changing flux densities within the new designs.

"The multiphysics simulation enables us to arrive at the top three designs, delivering not only time and cost savings in development but also optimized designs that meet the needs of our customers," Allen said. "There is a constant evolution at work."

"Generator users demand high-performance generators, with challenging goals for efficiency, size and durability," said Brad Hutchinson, global industry director, industrial equipment and rotating machinery at ANSYS. "Given the complex interaction of stress, cooling, electromagnetics and material properties, advanced multiphysics simulation is the only way that designers can gain the insights required to optimize and deliver the machine in a timely manner."

About ANSYS, Inc.

ANSYS brings clarity and insight to customers' most complex design challenges through fast, accurate and reliable engineering simulation. Our technology enables organizations ― no matter their industry ― to predict with confidence that their products will thrive in the real world. Customers trust our software to help ensure product integrity and drive business success through innovation. Founded in 1970, ANSYS employs over 2750 professionals, many of them experts in engineering fields such as finite element analysis, computational fluid dynamics, electronics and electromagnetics, embedded software, system simulation and design optimization. Headquartered south of

ANSYS also has a strong presence on the major social channels. To join the simulation conversation, please visit: www.ansys.com/Social@ANSYS

ANSYS and any and all ANSYS, Inc. brand, product, service and feature names, logos and slogans are registered trademarks or trademarks of ANSYS, Inc. or its subsidiaries in

ANSS-C

|

Contact |

Media |

Amy Pietzak |

|

|

724.820.4367 |

|||

|

|

|||

|

Investors |

Annette Arribas, CTP |

||

|

724.820.3700 |

|||

Photo - http://photos.prnewswire.com/prnh/20150518/216894

Logo - http://photos.prnewswire.com/prnh/20130430/NE03388LOGO

To view the original version on PR Newswire, visit:http://www.prnewswire.com/news-releases/brush-group-optimizes-turbogenerator-design-with-ansys-multiphysics-solutions-300086224.html

SOURCE ANSYS, Inc.